-

WhatsApp/Tel:008613526692320 Get costs

Pyrolysis Plant Manufacturers

Pyrolysis Plant design , custom , install , technical support

Pyrolysis plant / Waste oil to diesel machine chapter

Pyrolysis Plant

Raw Materials&Oil Yields

Rubber tire

Waste plastic

Oil sludge

Coal tar oil

Aluminum plastic composite material

35%-52%

35%-95%

Varies

Varies

Varies

-

Pyrolysis oil

-

Carbon black

-

Steel wire

-

Syn-gas

-

Aluminum ingot

Varies:Depending on the impurity content of the raw material, the oil yield will fluctuate greatly. For example, if there are many impurities in oil sludge, the oil yield will be only about 5%; if there are few impurities, the oil yield will be higher than 50%.

-

Pyrolysis Plant Types

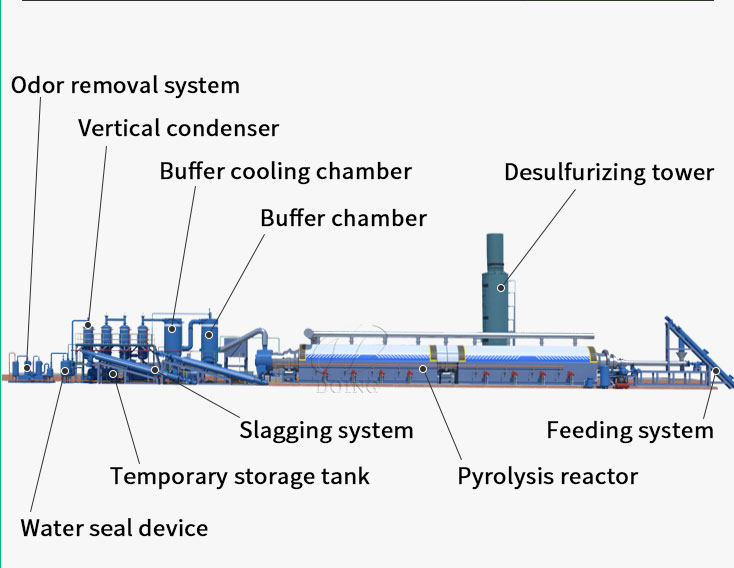

Option 1: New Design Fully Continuous Pyrolysis Plant

Daily Capacity: 15TPD, 20TPD, 30TPD, 50TPD, etc.

Fully Continuous Pyrolysis Plant Advantages

-

Automation PLC system

-

24 hours continuous production

-

Large processing capacity

-

Save time and energy

Fully Continuous Pyrolysis Plant StructureFully Continuous Pyrolysis Plant Cost

-

-

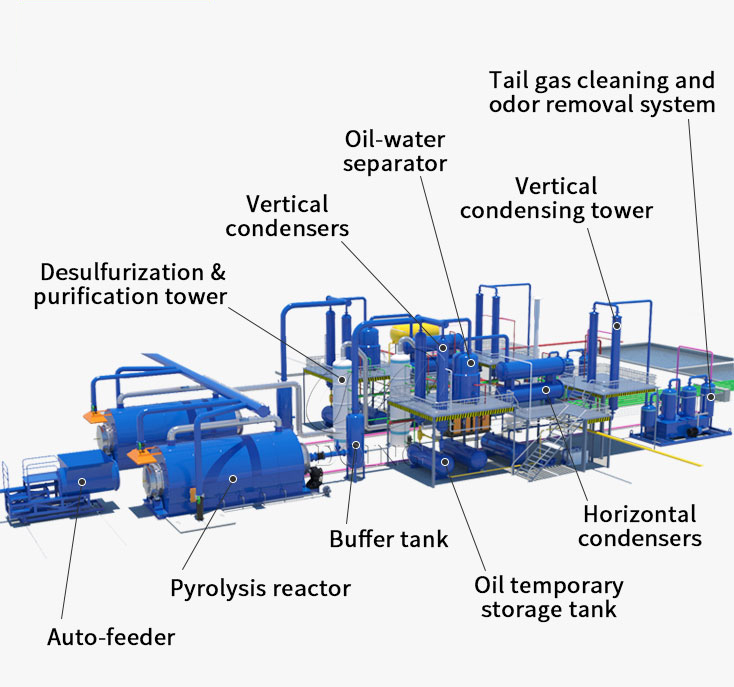

Option 2: High-efficiency Semi-continuous Pyrolysis Plant

Semi-continuous Pyrolysis Plant Cost

Semi-continuous Pyrolysis Plant CostDaily Capacity: 10TPD, 12TPD, 15TPD, 20TPD, etc.

Semi-continuous Pyrolysis Plant Advantages

-

Automatic feeding

-

High efficiency

-

Energy saving

-

Good performance

-

-

Option 3: Cost Effective Batch Type Pyrolysis Plant

Daily Capacity: 1TPD, 2TPD, 5TPD, 10TPD, 12TPD, 15TPD, 20TPD , etc.

Batch Type Pyrolysis Plant Advantages

-

Easy to operate

-

Cost-effective

-

Good stability

-

Multiple uses

Batch Type Pyrolysis Plant StructureBatch Type Pyrolysis Plant Cost

-

-

Option 4:Mini small pyrolsysis plant,no installation required

Mini small pyrolsysis plant cost

Mini small pyrolsysis plant costDaily Capacity: 100KG/D, 500KG/D

Small Pyrolysis Plant Advantages

-

Easy to install

-

Cost saving

-

Easy handling

-

Tests available

-

-

Final Products&Applications

-

Fuel oil

-

Boiler heating

-

Heavy oil generator

-

Refining into diesel

-

Syn-gas

-

Heating reactor

-

Burning

-

Aluminum

ingot -

Industrial manufacturing

-

Directly sell

-

Carbon black

-

Briquetting

-

Refining

-

Steel wire

-

Sold as scrap

-

Remelt

-

-

Pyrolysis Plant Profit Analysis

Profit analysis(15TPD waste tyre pyrolysis plant) Cost/Day Waste Tyre 15T*30USD/T =450USD Electricity Consumption 45 USD Heating Fuel(Coal/Tire oil/LNG) 0.6T*110USD/T=66USD Manpower 3 Workers* 50USD = 150USD Income/Day Pyrolysis Oil 6T* 600USD/T = 3600USD Carbon Black 4.5T * 50USD/T=225USD Steel Wires 2.25T* 220USD/T = 495 USD Daily profit=4320USD-711USD=3609USD All the above data comes from the Internet and customer feedback.Various data will vary with market fluctuations. All customers are welcome to contact Henan Doing Company for detailed profit analysis and pyrolysis plant customization.

Contact DOING

Contact DOING

If you want to know more about the pyrolysis plant, please fill in the information and leave your contact information. Our staff will reply to you in time. You can also call us or add us on whatsapp. +86 135 2669 2320.

-

Pyrolysis Plant Advantages

-

① Made of 16mm boiler plates

or 304/306 stainless steel;② Round-shape reactor head;

③ Withstand high pressure &

temperature. -

① 3-step welding process;

② One piece design;

③ No risk of cracking;

④ Long machine service life.

-

① Four materials insulation cover;

② Multiple fire protection tests;

③ Guaranteed quality control.

-

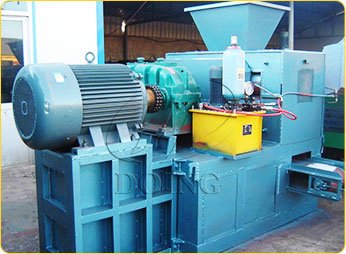

Carbon black wind transfer equipment

New pulse dust removal design, felt surface filter bag, fully enclosed, no dust, easy to clean.

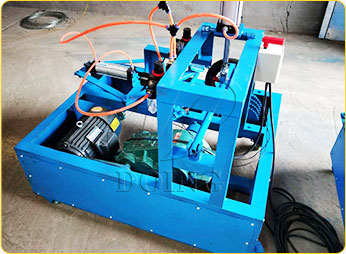

-

Exhausted gas cleaning equipment

Solve unpleasant odors and remove harmful gases such as H2S, NOx, Cox, etc.

-

Flue gas purification system

Fiberglass material, long service life, four sprays and four-layer ceramic filler to remove sulfur dioxide and solid particles.

-

-

Pyrolysis plant project related equipment

Contact DOING

Contact DOING

If you want to know more about the pyrolysis plant, please fill in the information and leave your contact information. Our staff will reply to you in time. You can also call us or add us on whatsapp. +86 135 2669 2320.

Waste/Crude Oil to Diesel Distillation Plant

Raw Materials&Oil Yields

Pyrolysis oil

Liquid oil sludge

Used

engine oil

Used

lube oil

Used

motor oil

Crude oil

Diesel:80%-85%

-

Oil Distillation Plant Machine Types

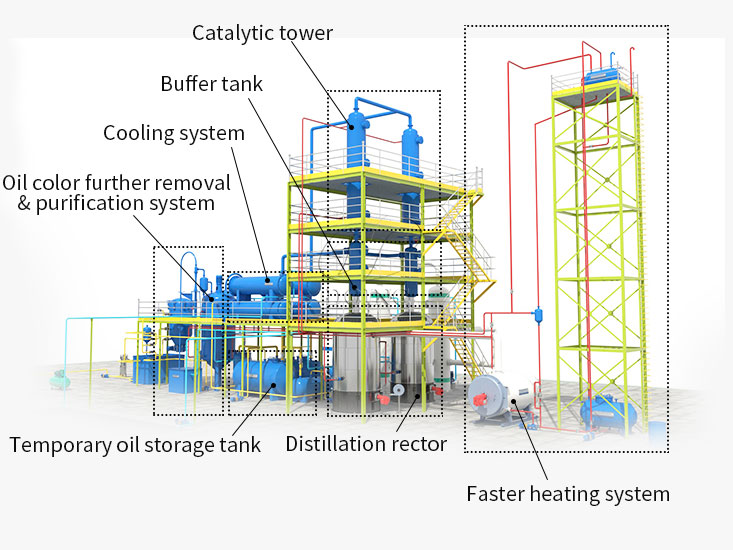

Option 1: New Catalytic Technology Waste Oil Distillation Plant

Daily Capacity:1TPD, 5TPD, 7TPD, 10TPD, 14TPD, etc.

Waste Oil Distillation Plant Advantages:

-

High efficiency

-

Easy operation

-

Time and labor saving

-

Multiple uses

Get a price

Get a price

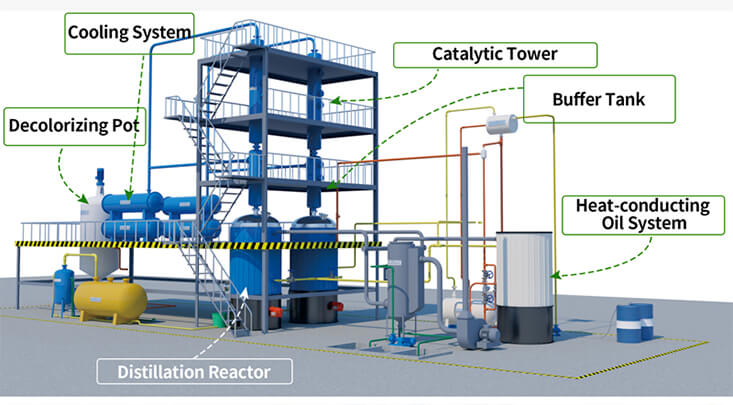

Option 2: Cost-effective Waste Oil Distillation Plant

Daily Capacity:1TPD, 5TPD, 7TPD, 10TPD, 14TPD, etc.

Cost-effective Waste Oil Distillation Plant Advantages:

-

Cost-effective

-

Easy to install

-

Energy saving

-

Steel frame construction

Get a price

Get a price

Option 3: Mini Small Waste Oil Distillation Plant

Get waste oil distillation plant costDaily Capacity: 100KG/D, 500KG/D

Mini Small Waste Oil Distillation Plant Advantages:

-

No installation required

-

Cost saving

-

Easy handling

-

Tests available

Tips: Our team of engineers can customize the right solution for you Maximize your benefits based on your actual needs

-

Final Products&Applications

-

Waste oil distillation plant profit analysis

Profit analysis of one set DOING 5TPD waste oil distillation plant Cost for one batch Item Consumption Crude oil 5T 1770$ Heating fuel consumption 500Kg 0.5*300$=150$ Water & Electricity consumption 24Kw (24Kw/h*10h) * $0.2 KW/H=48$ Catalyst 100$ Workers' salary 100$ Total cost: 2168$ Return for one batch Item Consumption Diesel 4.25-4.5T 4.25*870.24$=3698.52$ Bituman 0.5-0.75T 0.5*108$=54$ Total income: 3752.52$ Profit Daily profit 1,584.00$ Monthly profit(20days) 31,690.00$ Annual profit(10months) 316,904.00$ All the above data comes from the Internet and customer feedback.Various data will vary with market fluctuations. All customers are welcome to contact Henan Doing Company for detailed profit analysis and pyrolysis plant customization.

Contact DOING

Contact DOING

If you want to know more about the pyrolysis plant, please fill in the information and leave your contact information. Our staff will reply to you in time. You can also call us or add us on whatsapp. +86 135 2669 2320.

Waste Tire /Plastic to Diesel Plant

-

Option 1: Small Tire Plastic to Diesel Plant

( Daily capacity: 100KG/D, 500KG/D )

-

Tyre plastic pyrolysis plant

-

Pyrolysis oil to diesel refinery plant

Small tire plastic to diesel refinery plant advantages

Get Small Tire Plastic to Diesel Plant Costs

Get Small Tire Plastic to Diesel Plant Costs

Option 2: Middle/Big Scale Tire Plastic to Diesel Plant

( Daily capacity: 1TPD, 2TPD, 5TPD, 10TPD, 12TPD, 15TPD, 20TPD, etc.)

-

Tire plastic pyrolysis plant

-

Pyrolysis oil to diesel refinery plant

Middle/Large Scale Tire Plastic to Diesel Plant Advantages

Get Tire Plastic to Diesel Plant Costs

Get Tire Plastic to Diesel Plant Costs

Option 3: Plastic to Diesel and Gasoline Integrated Plant

( Daily capacity: 1.5TPD, 2.5TPD, 5TPD, 10TPD, 20TPD, etc. )

Plastic to Diesel and Gasoline Integrated Plant Advantages

Get Plastic to Diesel and Gasoline Integrated Plant

Costs

Get Plastic to Diesel and Gasoline Integrated Plant

Costs

-

Other waste tyre equipment

Contact DOING

Contact DOING

If you want to know more about the pyrolysis plant, please fill in the information and leave your contact information. Our staff will reply to you in time. You can also call us or add us on whatsapp.+86 135 2669 2320.

Pyrolysis Plant Project Cases

-

China

-

Kazakhstan

-

Russia

-

Italy

-

Georgia

-

India

-

Vietnam

China

-

Chile

-

Malaysia

-

Colombia

-

Kyrgyzstan

-

Malaysia

-

Côte d'Ivoire

Australia

-

Mexico

-

Nigeria

-

America

-

China

-

France

-

Indonesia

-

Thailand

-

China

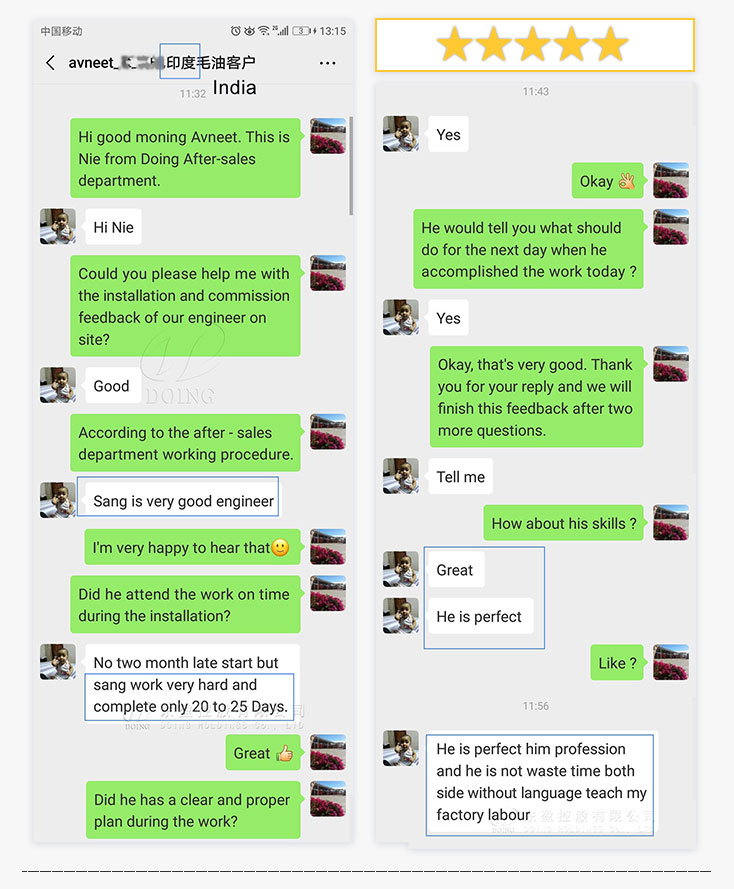

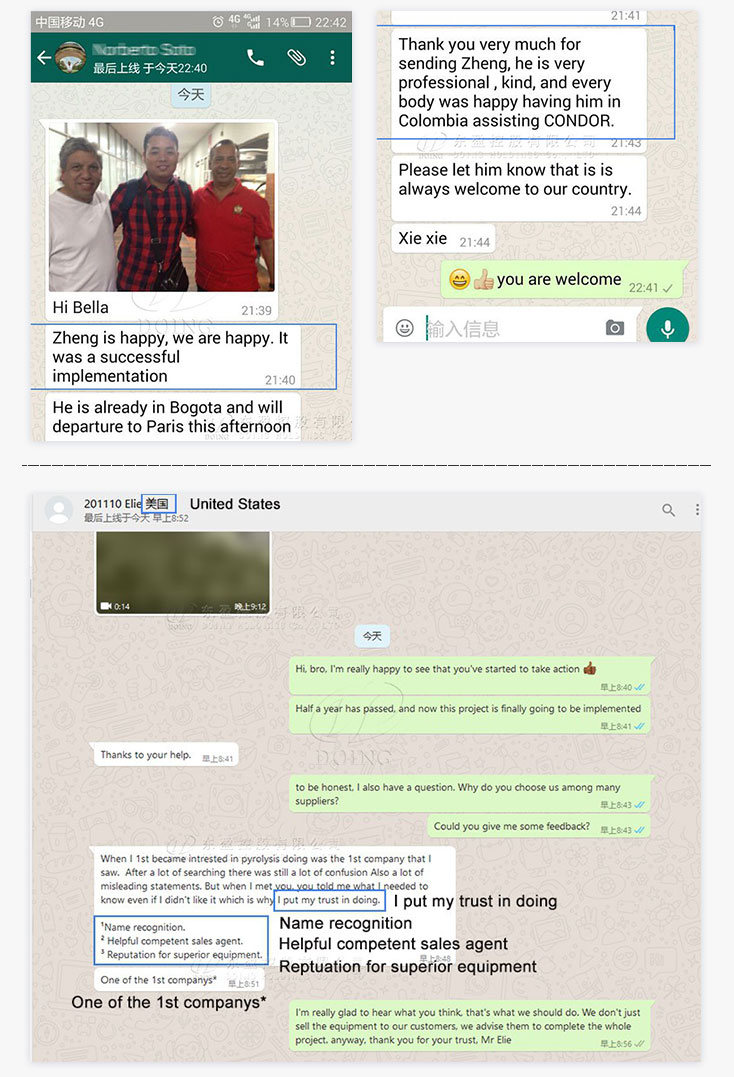

Customer Feedback

Company Profile

Henan Doing Environmental Protection Technology Co., Ltd is a subsidiary of Doing Holdings Co., Ltd. We are a leading manufacturer of comprehensive environmental equipment. Our expertise lies in technological design, research and development, machine production, sales, and after-sales service.

Relying on excellent technical R&D strength and innovative spirit, our company has won up to 23 new utility patents and invention patents. And our company is honored as the National High Technology Enterprise awarded by the Municipal Science and Technology Commission. Now, our products sell well in 100+ countries and regions around the world.

Our manufacturing factory convers an area of 40000+㎡, Welcome to visit our location and test our machines with the materials. Additionally, we have a branch office and an overseas warehouse. We are also in the process of building a fabrication factory in Nigeria, Africa (19B Kudirat Abiola Way Olusosun Bus stop, Ikeja, Lagos, Nigeria) to make it even more convenient for customers to pick up machines directly from the warehouse.

24/7 SERVICE

-

2000+

Our Customers

-

100+

Exporting Country

-

50+

Technical Engineer

-

20+

Install Team

-

100K+

Intentional Customers

-

24H

Technical Support

Service Content

-

-

01Pre-sale Services

1. Visit the DOING factory

1. Visit the DOING factory

2. Complete solution for face-to-face communication equipment

2. Complete solution for face-to-face communication equipment

3.Planning factory equipment configuration

3.Planning factory equipment configuration

-

-

02On-sale Service

1. Visit and inspect the production progress of the machine

1. Visit and inspect the production progress of the machine

2. Confirm equipment manufacturing status

2. Confirm equipment manufacturing status

3. Confirm delivery method and delivery date

3. Confirm delivery method and delivery date

-

-

03After-sale Service

1. One-year warranty

1. One-year warranty

2.Guide equipment installation, debugging and operation

2.Guide equipment installation, debugging and operation

3. Technical training and guidance

3. Technical training and guidance

DOING HOLDINGS

Henan Doing Environmental Protection Technology Co., Ltd

WhatsApp/Wechat:

+86 13526692320

Email:

market@doinggroup.com